How Many Ground Rod Should I Bury For A 200 Amp Service

chvet73

| I am adding power to a new garage workshop. It is 125 away from panel to panel. Origin panel is 200 amp and sub panel is 100 amp. I calculate this at 1/0 AL or 1 copper. Im leaning toward AL due to cost. Just wanted to see if you guys agree with wire size. Thanks in advance for your replies. |

Destroked 450

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see In my area when running under ground thru conduit if crossing a roadway that conduit must be run thru a larger conduit, to protect the primary conduit from crushing due to soil compaction caused by vehicles traveling the roadway, a second option is to use schedule 80 PVC conduit When building the last saw mill we ran aluminum tri wire provided by the local utility company under ground thru schedule 80 PVC for 240 ft to a ground based transformer, from the transformer we ran 6 sets of 600 MCM aluminum underground to the building were it connected to a 2000 amp switch gear in the power room All wiring inside the building past the switch gear was copper |

Brian G. NY

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see The cable I used to run power to my barn is labeled URD. I believe this is common "entrance cable" and can be run either overhead or underground. |

| |

DoubleO7

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Since your ground is so rocky, good idea on running the feed in conduit |

| |

zuhnc

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Underground conduit is considered a WET location, and the wire within MUST be rated for WET conditions. Also, if one uses a 4-conductor cable, it MUST be rated for use within conduit. I ran 1" conduit 130 feet to my horse barn, and used #6 THHN copper. I don't use aluminum for anything. This THHN is rated for 75 A, but I have it on a 60 A circuit breaker. A little overkill, but plenty of capacity for barn improvements and upgrades. Having a permit is nice, but does not guarantee up to code; depends on the inspector and AHJ. |

John T

Re: Electrical question in reply to zuhnc, 11-28-2021 15:04:36

| Underground conduit is considered a WET location, and the wire within MUST be rated for WET conditions True, I typically specified THWN insulated conductors in buried conduit.........in our jurisdiction John T |

| |

dr sportster

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

Brian G. NY

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| [quote="Dusty MI"](quoted from post at 22:16:47 11/28/21) Quoting Removed, click Modern View to see ___________________________________________________________________________ When I built my house in 1995, Niagara Mohawk (now National Grid) ran aluminum from the high line to the transformer pole and on to a pole 100 ft. from my house. The contractor ran the aluminum service cable from that pole to my main panel underground in 2" PVC conduit. Direct burial of "triplex" service cable doesn't sound like a good idea to me but I haven't bothered to look it up. |

Dusty MI

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see |

| |

Dusty MI

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see |

| |

Ted in NE-OH

Re: Electrical question in reply to Dusty MI, 11-28-2021 13:21:04

| Wire in conduit is protected fro shovels and allows for some expansion or contraction as the earth moves. |

| |

Bob Bancroft

Re: Electrical question in reply to Dusty MI, 11-28-2021 13:21:04

| I'm wondering the same thing. I suppose occasionally the ground may dry out, whereas the water in the conduit won't? My concern with underground wire is keeping it from getting squashed under a driveway, or getting sliced with a shovel near a foundation. So I go with conduit. |

| |

Dusty MI

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see Last I knew AL-aluminum conduit is not allowed underground. So is AL wire allowed underground ? |

| |

Stephen Newell

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| The majority of service wire is aluminum. Sized correctly I don't see any issue. Make sure you install a ground rod just for the sub-panel. |

| |

1948CaseVAI

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see I don't think I have ever called BS on here before... But I don't think anyone has an insurance denial over their service entrance line being aluminum. In my area you could not buy a copper service line from Evergy if you wanted to. The OP question is not about building wiring, it is about service wiring to feed a sub from a main. In fact I am not sure any HVAC contractors near me will wire your outdoor compressor with copper but not sure about all of them. I know my HVAC contractor will not use copper for the 220. |

Brian G. NY

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Quoting Removed, click Modern View to see ___________________________________________________ "Interior" wiring with aluminum is an accident waiting to happen. My wife's Uncle wired an addition to his house back in the 60s using aluminum. My son wound up with the house later and with 5 young kids, that electrical system was strained to it's limits. He began getting blinking lights and smoking outlet boxes which can be pretty scary. We wound up replacing all the aluminum wire with good ol' copper. |

Brian G. NY

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| 1/0 certainly looks adequate....as "Geo-TH, In", says, you should run four wires, two "hots", a neutral and a ground. Here's my lonng story about my similar installation: In 1995 I ran 100 amp service to my pole barn from my 200 amp panel at the house. It is a 230 ft. run and I used 2/0 aluminum with neutral in 2" conduit buried 5' deep (below frost) in the same ditch as the water line. Aluminum is certainly OK for entrance service or running a sub panel. I don't see the power companies using copper any more! In addition to the required 2 grounding rods, I strung about 35 ft. of heavy copper cable salvaged from an old lightning rod system around the perimeter of the dry well I dug for the barn. Ten years later, in 2005, I started reading posts by John T. and others about the necessity of separating the neutral and ground in an outbuilding panel. Well, after studying it for awhile and finally, after "getting it", I installed a separate ground wire going all the way back to my main panel. I used #4 bare solid copper which I got for just under a hundred dollars at the time and buried it about a foot underground. It is now essentially an extension of the grounding system. The original neutral, of course, is not insulated but is contained within the 2" PVC conduit which spans the entire distance between the two panels. That may be the flaw in my system, but I feel comfortable with it. The ground and neutral bars in the sub-panel are now isolated from one another. |

John T

Re: Electrical question in reply to Brian G. NY, 11-28-2021 08:39:05

| You state you should run four wires, two hots, a neutral and a ground. EXACTLY as myself and others noted that's how it's been a long time and was when I last practiced power distribution assuming its 120/240 Volt Single Phase Three Wire.. The remote building electrical service requires Grounding to a proper Grounding Electrode or Electrodes. Your buried copper wire is another excellent Grounding Electrode CONGRATULATIONS. In our jurisdiction per the NEC we were required to Ground to ALL READILY AVAILABLE GROUNDING ELECTRODES. If none were available we used a MADE ELECTRODE such as driven into earth ground rods We NEVER ran the Hot or Ground or Neutral separately but all together. If in metallic conduit the Ground Wire had to be insulated not bare Your system should work just fine yayyyyyyyyyyyyyyyyyyyyyy Nice sparky chatting with you, best wishes take care John T |

Dusty MI

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| I never liked to use direct buried. PVC conduit is not very expensive. If something should happen to that direct-buried wire you'll have to dig that trench again, and if it's winter. And there is nothing wrong with going over size with the conduit, then if something comes along and you need more power, you can just change to larger wire. |

| |

sotxbill

Re: Electrical question in reply to Dusty MI, 11-28-2021 07:14:31

| Trouble with conduit is.. Not if-it will fill with water, its just how fast... due to condensation. So if you put it in conduit, will will be wet most of its life. And this will shorten the life of the cable run. ymmv. |

| |

John T

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Direct buried Aluminum Underground cable is commonly used provided anti oxidant and correct torque and terminals. If powering a remote SUB PANEL fed off the MAIN, the SUB needs separate insulated and isolated NEUTRAL and EQUIPMENT GROUND BUSSES as well as bonding to a Grounding Electrode (such as a MADE electrode like a driven ground rod or rods) out at the SUB. For 120/240 Volt that means you need to run FOUR wires out, Two Hots L1 & L2, Neutral, Ground. Where Direct Bury Cable comes up out of the earth say into an LB into a building we had to use rigid conduit. John T NO WARRANTY Im longggggggggg retired from Power Distribution and rusty as an old nail on the latest NEC |

Geo-TH,In

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Aluminum for service entrance is common unless you have money to burn. |

| |

DoubleO7

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

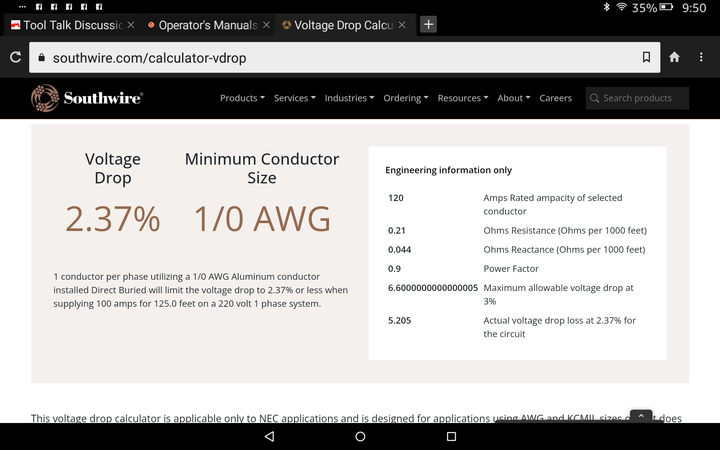

| Per Southwire website calculator.... |

| |

chvet73

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| I wouldnt wire a house with aluminum but I always thought for a service entrance it was fine. And I thought that most new homes had aluminum service entrance in this day and age. Of course Im sure I could be wrong about that. |

| |

old

Re: Electrical question in reply to chvet73, 11-27-2021 17:00:12

| Yes for service entrance it is just fine. The power companies use it for thousands of miles. Back in May or 2003 when the tornadoes came through this area the power company had to replace a bunch of there service wires. I asked about it since they would just leave it lay beside the roads. They said take it if you want it and I did |

| |

Russ from MN

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| Aluminum works just fine if you use contact paste properly, I'm pretty sure that's what most everyone uses, there is a big price difference! |

| |

Billy Shafer

Re: Electrical question in reply to Russ from MN, 11-27-2021 16:38:54

| I would not use Aluminum. Seen to many fires started. But if you are going to use it. Get the paste to go with it. Insurance may be hard to get. If you can it will cost you. |

| |

old

Re: Electrical question in reply to Billy Shafer, 11-27-2021 20:16:46

| Well guess your not up to date. From most poles to weather head they use aluminum etc. So from one service panel to another it is pretty much the norm |

| |

Goose

Re: Electrical question in reply to chvet73, 11-27-2021 14:37:57

| If you're talking about aluminum, I'd rethink that. Insurance companies take a dim view of aluminum wiring. |

| |

Billy Shafer

Re: Electrical question in reply to Goose, 11-27-2021 15:55:51

| I have seen many homeowners left holding the bill. When insurance found that wire. I set a test lab on fire. When my load banks set the wiring on fire. Fire marshal found Aluminum instead of copper. |

| |

chvet73

Re: Electrical question in reply to Billy Shafer, 11-28-2021 09:46:52

| 1st thanks to everyone for their replies. Heres what Im planning on doing: |

Latest Ad:

1953 farmall M excellent condition [More Ads]All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy

TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Website Accessibility Policy

How Many Ground Rod Should I Bury For A 200 Amp Service

Source: http://www.yesterdaystractors.com/cgi-bin/viewit.cgi?bd=toolt&th=512368

Posted by: lomeliyousintor.blogspot.com

0 Response to "How Many Ground Rod Should I Bury For A 200 Amp Service"

Post a Comment